S6000 COMPLETE SET: 6 pieces is all that you need if your daily work mainly deals with mini-splits lines. This economic set gets exactly what you want: from 1/4″ up to 7/8″.

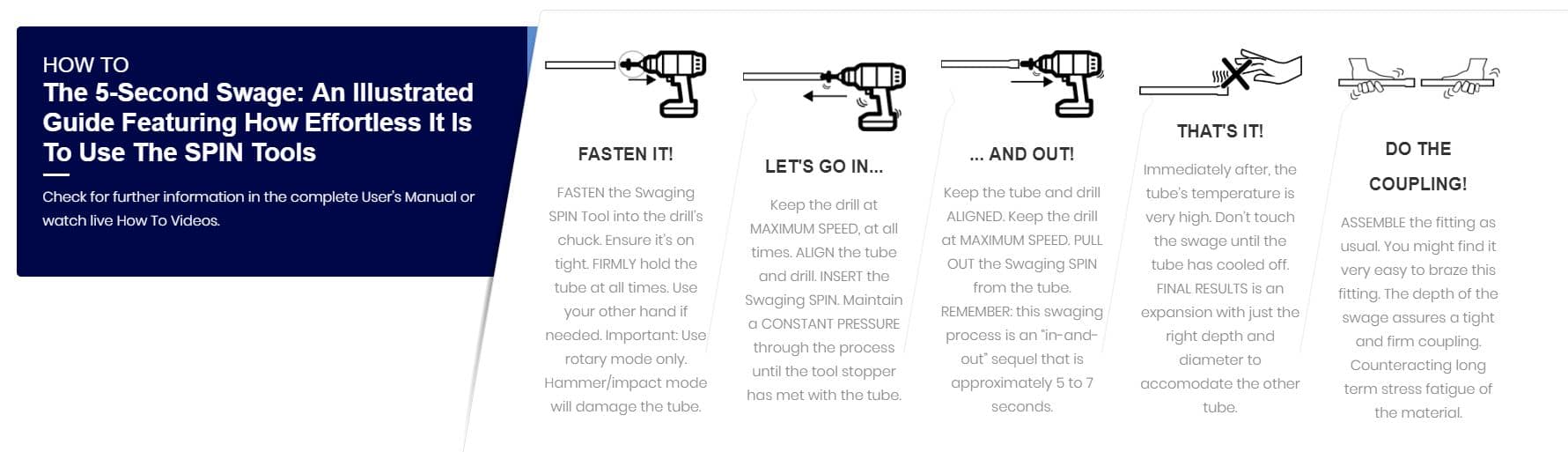

Swaging SPIN Better Quality Expansions! Less Joints! Forms soft and rigid copper. Using the Swaging SPIN you will have half the braze joints, decreasing drastically the probability of leaks. You save money by dispensing additional fittings. The Spin tool is designed to deliver an ideal swage depth to each tube diameter, minimizing the vibration fatigue phenomenon, and giving a better assurance of leak-free systems.

The Swaging SPIN Tool is designed for the most common tubing diameters in HVAC, and it’s recommended to both soft and hard copper. The high-temperature method preserves the copper’s/aluminium’s malleability while performing the swage, preventing cracks and leaks.

Spin Tools are the flagship product from Cimport, a company operating in the Brazilian’s HVAC market for about 22 years that brings to market smart tools for HVAC-R professionals.

SPIN S6000 Swaging Set Features:

- Compatible with 1/4″ – 3/8″ – 1/2″ – 5/8″ – 3/4″ – 7/8″ tube sizes

- Flawless swages in five seconds

- Universal drill compatibility

- The reusable tool with long-life design

- Innovative new technology

- Heat by friction

- Works with soft copper creating less cracks

- To use with hard cooper just preheat the cooper.

- 12-month warranty.

SPIN S6000 Swaging Set Includes:

6 x individual Spin swaging tools: 1/4″ – 3/8″ – 1/2″ – 5/8″ – 3/4″ – 7/8″, 1 x Storage Box, 1 x English user manual and 12-month warranty.

SPIN S6000 Swaging Set Specifications:

- Model: S6000

- Brand: SPIN

- Country of Origin: Brazil

- Material: Steel, Alloy

- Shipping weight: 0.40 Kg

- Copper tube sizes 1/4″ – 3/8″ – 1/2″ – 5/8″ – 3/4″ – 7/8″

- Maximum tube wall thickness: 0.8mm (1mm for 5/8th).

All SPIN Tools are designed to work with drills and/or screwdrivers, with a minimum of 1,800 RPM and 500 watts, for corded drills, or superior and 1,800RPM and 18V, or superior, for cordless drills. Using the SPIN Tools with a less powerful equipment tool than suggested, may result in decreased and low-quality performances.