Infrared thermometers are the most common tool used for non-contact temperature measurements. Another common tool is thermal imagers which have wider and more sophisticated features. Infrared thermometers and thermal imagers are similar in the fact they both detect infrared radiation and turn it into a temperature reading. However, thermal imagers have several advantages compared to infrared thermometers.

- Infrared thermometers give you a number – thermal imagers generate a heat image.

- An infrared thermometer reads the temperature of one single spot – a thermal imager gives you temperature readings for each pixel of the entire thermal image.

- Because of advanced optics, thermal imagers can also resolve temperatures from a longer distance. This allows you to quickly inspect large areas.

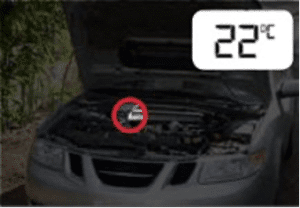

Infrared thermometers are also known as temperature guns or thermometers. They are useful for many tasks but because they only measure the temperature of a single spot, there is the potential that the operator could miss crucial information and the high temperature of certain components that are near failure could go unnoticed.

The UT300S infrared thermometers is a temperature gun that measures the exact temperature of one spot.

The Uni-T uti320v thermal imager measures the temperature of 307,200 spots.

Use Thousands of Infrared thermometers at the Same Time

A thermal imager also provides non-contact temperature readings, just like a infrared thermometer does. Unlike an infrared thermometer, thermal imagers produce not one, but thousands of temperature readings at the same time, one for each pixel in the thermal image. Using one thermal imager therefore corresponds to thousands of infrared thermometer measurements. The Uni-T UTI320V thermal imager has an image resolution of 620 x 480 pixels, resulting in 307,200 temperature readings at a glance.

A thermal imager provides non-contact temperature readings, just like a infrared thermometer. Thermal imagers, unlike a infrared thermometer, produces not one but thousands of temperature readings, one for each pixel in the thermal image. The Unit-T UTI320V thermal imager has a image resolution of 620×480 pixels, this results in 307,200 temperature readings.

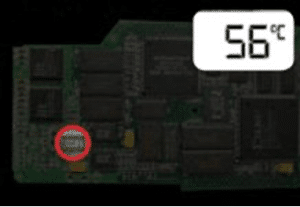

What a infrared thermometer ‘sees’.

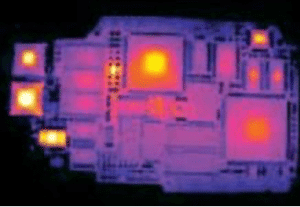

What a thermal imaging camera ‘sees’.

What a infrared thermometer ‘sees’.

What a thermal imaging camera ‘sees’.

How Infrared Technology Works

Infrared energy is described as light we can not see. Thermal imager sees the light as heat and shows this in the infrared picture. Each picture is allocated a colour which is based on the temperature the thermal imager is reading. The temperature range is shown on a colour scale. Moisture takes longer to heat up and cool down compared to other objects in a scene causing a hot or cold temperature difference, which the infrared camera can see as heat. All materials whose surface temperature is above absolute zero (-273°C) emits infrared (heat).

All infrared waves are thermal. The infrared information of objects that radiate heat are passed to a signal processor which translates the infrared data into an image that can be viewed and the infrared images along with normal digital images can be stored for late documentation in the cameras reporting software.

Save Time and ‘See’ the Heat

A thermal imager gives you thousands of temperature readings and it also translates these readings into a thermal image. This results in a complete overview of the inspected equipment and the operator can immediately spot hot spots that would be easily missed with a infrared thermometer. Scanning large areas with many components is time consuming with a infrared thermometer because you have to scan every component separately. With a thermal imager this can all be done in one go. A thermal imager can be used to check heat dissipation on printed circuit boards, quality checks or inspect thermal impact in the automotive sector, or to do failure analysis in the lab.

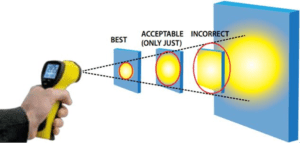

In order to accurately measure an object’s temperature with a infrared thermometer the target object needs to entirely cover the measurement spot. This limits the distance from which temperatures can be measured accurately.

The Spot Size Ratio (SSR) defines a infrared thermometers spot size for any given distance. Due to the nature of optics, the spot your measuring will be larger the farther away you hold the infrared thermometer from the object. The smaller the object the closer you need to hold the infrared thermometer in order to get a accurate measurement. It is therefore important to keep an eye on the spot size and make sure that you stand close enough to cover the entire spot size with the target.

If the SSR of a infrared thermometer is 1:30, for instance, this means that the temperature of a spot with a size of 1 cm in diameter can be accurately measured at a distance of 30 cm. The temperature of a spot having a size of 4 cm can be measured for a distance of 120 cm (1.2 meters). Most infrared thermometers have an SSR between 1:5 and 1:50. This means that most infrared thermometers can measure the temperature of a target of 1 centimetre in diameter for a distance of 5-50 cm.

Thermal imagers also have a range of key specifications that need to be carefully considered prior to purchasing including FOV, Resolution, Thermal Sensitivity, Focus and range.

Field of View (FOV)

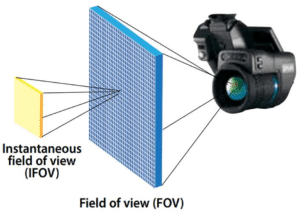

Field of View is determined by the camera lens, and is the extent of a scene that the camera will see at any given moment. For work being done close-up, you need a lens with a wide angle FOV (45° or higher). For long distance work, you need a telephoto lens (12° or 6°). Some cameras may be available with multiple lenses for different applications.

Thermal imagers allow you to ‘see’ the heat.

IR Resolution

The resolution of the camera is how many pixels the camera has on the scene. Higher resolution means that each image contains more information: more pixels, more detail, and a greater likelihood of getting an accurate measurement. Measuring smaller targets from further away will require a higher resolution.

Thermal Sensitivity (NETD)

Thermal sensitivity or Noise Equivalent Temperature Difference (NETD) describes the smallest temperature difference you can see with the camera. The lower the number, the better the thermal sensitivity of the infrared system.

If the targets you need to measure typically have wide temperature differences, a camera with a low NETD probably isn’t necessary. However, for more subtle applications, like detecting moisture issues, you will need more sensitivity.

Focus

Thermal imagers may be

- fixed focus, meaning they are always in focus

- have manual focus, meaning the user adjusts the focus on the camera

- automatic focus, meaning the camera will autofocus based on what it can see for contrast on the scene.

In general, more entry level cameras will have fixed focus, and high-performance cameras will have either manual or automatic focus. The advantage of manual vs. automatic focus comes down to user need.

Spectral range

Spectral range is the range of wavelengths that the sensor in the camera detects, measured in micrometers (µm). Most gas detection cameras (such as propane, methane, and butane detectors) are midwave cameras, meaning they have a spectral range of 3µm to 5µm. Almost all other thermal imagers are longwave, and have a spectral range of 8µm to 14µm. Longwave cameras are appropriate for most other applications, from electrical inspections to firefighting.

Stop Guessing, Start Seeing

A infrared thermometer can only give you a number. That number might be inaccurate, which leaves you guessing. A thermal imager allows you to ‘see’ the heat, giving you not only temperature measurements, but also an instant image of heat distribution. This combination of visual information and accurate temperature measurements enables you to find faults quickly and accurately.

Stop guessing, upgrade to a professional thermal imager from Uni-T and start finding problems faster and easier.